Telephone: +8618730949119

E-mail: 1299343081@qq.com

Jul . 30, 2025 04:20

Back to list

Premium Window Weather Stripping for Doors & Cars | Durable Seal

Exploring weather stripping door bottom, automotive weather stripping, car weather stripping, auto weather stripping solutions

Visit Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim Product Page

Visit Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim Product Page

Industry Trends in Window Weather Stripping

Market Growth (2024-2030): The global weather stripping market is projected to reach USD 13.1 billion by 2030, with a CAGR of 7.8% from 2024 (source). The automotive segment holds the largest share due to increasing demand for advanced car weather stripping and auto weather stripping solutions focused on efficiency, comfort, and compliance with regulatory standards.

- Increased energy efficiency regulations in North America and Europe drive both window weather stripping and weather stripping door bottom adoption in residential and commercial construction.

- Automotive applications (OEM/aftermarket) are experiencing a shift toward EPDM and TPV (Thermoplastic Vulcanizate) rubber for superior sealing and weather resistance.

- Smart weather stripping with integrated sensors (for windows, doors, and cars) is emerging in high-end installations.

- Focus on sustainability & recyclability is shaping material choices across automotive weather stripping manufacturers.

Global Weather Stripping Market Share by Application, 2023 (Source: Allied Market Research)

What is Window Weather Stripping?

Window weather stripping refers to the process and products designed to seal gaps around windows (and doors), preventing air, water, dust, and noise intrusion. In automobiles, specialized car weather stripping is a critical component for passenger comfort, structural protection, and longevity.

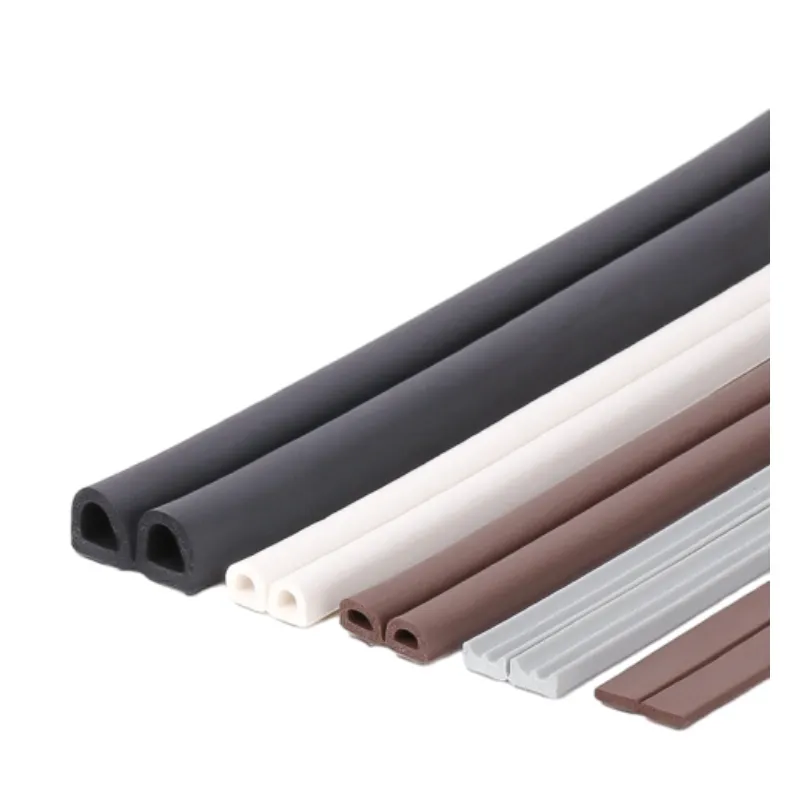

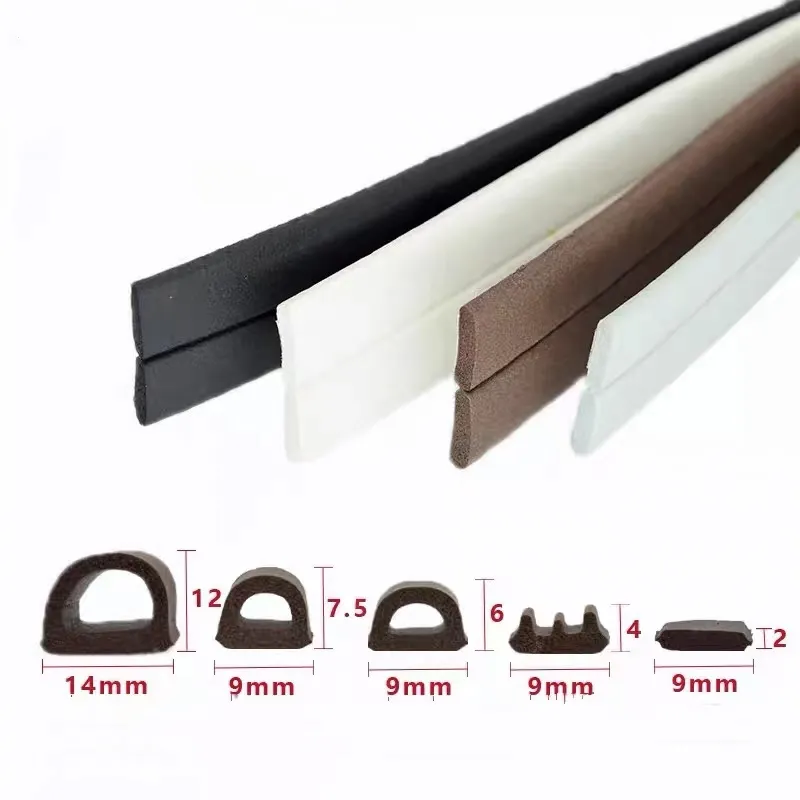

- Common materials: EPDM, silicone, natural rubber, neoprene, PVC/TPV, and innovative foam blends.

- Types: Bulb seals, blade seals, D-profiles, P-profiles, adhesive-backed strips, magnetic seals, glass run channels.

- Key parameters: Compression set, durometer (hardness), UV resistance, ozone/weather resistance, flexibility, and chemical inertness.

Technical Parameters of Window Weather Stripping Solutions

| Parameter | Standard Value (Industry Range) | Application (Window / Door / Auto) | Importance |

|---|---|---|---|

| Material | EPDM / TPV / Silicone / PVC Foam | Window, Door, Auto | Weather resistance, durability |

| Hardness (Shore A) | 55–70 | Window, Door, Auto | Compression/Recovery |

| Compression Set | Window, Auto | Maintains seal | |

| UL/Flame Rating | UL94 HB / V-0 | Automotive, Building | Safety |

| Operating Temperature | -40°C ~ +125°C | All | Environment/Climate Suitability |

| UV/Ozone Resistance | Good–Excellent | Outdoor Usage | Longevity |

| Water Leakage Test | No visible leakage at 15 l/min, 10min (ISO 9227) | Auto, Window | Protection |

Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim: Product Overview

Product: Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim

Product Link: Visit Product Page

Target Applications: Automotive window/door sealing, lip bumpers, fender flares, wheel arches, glass run weatherstripping, auto weather stripping upgrades.

Material: EPDM or Modified Rubber Compound

Temperature Range: -50°C ~ 120°C (-58°F to 248°F)

Durometer Hardness: 60±5 Shore A

Compression Set: ≤20% (ASTM D395)

UV/Ozone Resistance: Excellent

Customization: Length, cross-section profile, adhesive backing, color (OEM/ODM)

Certifications: ISO 9001:2015, RoHS, REACH, SGS tested

Product Link: Visit Product Page

Target Applications: Automotive window/door sealing, lip bumpers, fender flares, wheel arches, glass run weatherstripping, auto weather stripping upgrades.

Material: EPDM or Modified Rubber Compound

Temperature Range: -50°C ~ 120°C (-58°F to 248°F)

Durometer Hardness: 60±5 Shore A

Compression Set: ≤20% (ASTM D395)

UV/Ozone Resistance: Excellent

Customization: Length, cross-section profile, adhesive backing, color (OEM/ODM)

Certifications: ISO 9001:2015, RoHS, REACH, SGS tested

Product Technical Specification Comparison

| Product | Material | Hardness (Shore A) | UV Resistance | Compression Set | Operating Temp | Certifications |

|---|---|---|---|---|---|---|

| Universal Rubber Sealant | EPDM/Mod. Rubber | 60±5 | Excellent | ≤20% | -50~120°C | ISO9001, RoHS, SGS |

| Generic OEM Car Weatherstrip | EPDM/PVC Mix | 65±7 | Good | ≤30% | -40~100°C | ISO9001 |

| Door Bottom Stripping | Silicone/TPV | 55±5 | Good | ≤25% | -30~110°C | RoHS |

| Industrial HVAC Seal | Neoprene | 70±5 | Good | ≤30% | -20~100°C | SGS |

Compression Set Comparison (Lower is Better)

Manufacturing Process of Window Weather Stripping (Automotive/Construction)

1. Compound Preparation

High-quality EPDM/special rubber blending.

(ISO/ASTM grade raw material)

→

High-quality EPDM/special rubber blending.

(ISO/ASTM grade raw material)

2. Extrusion/Shaping

Rubber extrusion via die (custom profiles).

High-precision CNC dies for tight tolerances.

→

Rubber extrusion via die (custom profiles).

High-precision CNC dies for tight tolerances.

3. Vulcanization

Heat-curing to cross-link polymers, boosting elasticity and durability (per ASTM D412).

→

Heat-curing to cross-link polymers, boosting elasticity and durability (per ASTM D412).

4. Surface Treatment

Optional flocking, adhesive application, UV-protective or anti-squeak finishing.

→

Optional flocking, adhesive application, UV-protective or anti-squeak finishing.

5. Cutting & QC Inspection

Precise length cutting, 100% inspection for leakage, compression, hardness.

(ISO 9001/ANSI Z94.6)

→

Precise length cutting, 100% inspection for leakage, compression, hardness.

(ISO 9001/ANSI Z94.6)

6. Packing & Delivery

Labeling, customized packaging, global shipping.

Labeling, customized packaging, global shipping.

Technical Advantages of Modern Window Weather Stripping

- Superior Weather Resistance: High-grade EPDM & TPV blends offer >10 years UV/ozone durability (ISO 4892), maintaining flexibility and structural integrity.

- Thermal & Acoustic Efficiency: Advanced sealing geometry and material density reduce air leaks & external noise, improving building HVAC and car weather stripping comfort.

- Anti-Corrosion: Resistant to salt, oil, and chemical agents per ASTM D1149, crucial for automotive/industrial use.

- Easy Installation: Custom-cut, self-adhesive options reduce labor and error on-site or in aftermarket upgrades.

- Customization: CNC machined dies enable nearly unlimited profile designs to meet the demands of modern facades, energy codes, and vehicle aerodynamics.

Application Scenarios and Case Studies

Automotive Case Study:

A European OEM transitioned to Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim for its new SUV lineup. Required >120,000 door/arch weather strips that withstand -30°C to 50°C and maintain compression recovery >80% after 5 years.

Result: Warranty claims for wind noise, water leaks and corrosion dropped by 60%, resulting in a Tier-1 supplier award for 2022.

Certification: Product passed ISO 9227 salt spray and ASTM D2240 hardness tests.

A European OEM transitioned to Universal Rubber Sealant For Lip Bumper Car Fender Flare Arch Trim for its new SUV lineup. Required >120,000 door/arch weather strips that withstand -30°C to 50°C and maintain compression recovery >80% after 5 years.

Result: Warranty claims for wind noise, water leaks and corrosion dropped by 60%, resulting in a Tier-1 supplier award for 2022.

Certification: Product passed ISO 9227 salt spray and ASTM D2240 hardness tests.

Residential/Commercial Buildings:

A Canada-based energy retrofit contractor utilized advanced window weather stripping to overhaul 220+ apartment blocks. Measured HVAC energy savings of 18% were observed using independent monitoring (DOE, 2023).

A Canada-based energy retrofit contractor utilized advanced window weather stripping to overhaul 220+ apartment blocks. Measured HVAC energy savings of 18% were observed using independent monitoring (DOE, 2023).

Industrial Pipeline Seal Upgrade: For a water treatment facility, custom-blended rubber weatherstrip (ISO 14001 grade) was deployed. Chemical resistance and sealing performance reduced maintenance downtime by 43%.

Predicted Service Life: Universal Rubber Sealant vs. Generic OEM (Accelerated Aging, ASTM G154)

Leading Manufacturers and Industry Comparison

| Brand/Factory | Main Products | Certifications | Countries Served | Strengths |

|---|---|---|---|---|

| QZSeals | Automotive Window/Door/Arch Weather Stripping Universal Rubber Sealant |

ISO 9001, RoHS, REACH, SGS | 70+ | Customization, strict QC, 15+ years experience |

| Cleveland Rubber | Architectural/Automotive Seals | ISO 9001 | 50 | Quick turn prototyping, US facility |

| Henniges Automotive | OEM Rubber/TPV Auto Weatherstripping | ISO/TS 16949 | Global | Tier 1 automotive OEMs, advanced lab test |

| Q-Lon Seals | Polyurethane, Eco/Green Strips | ISO 14001 | 60 | Sustainability, European standards |

Custom Window Weather Stripping Solutions

- OEM/ODM Manufacturing: Cross-section, durometer, backing, color, and packaging all tailored to customer/industry requirement.

- Application Engineering: On-site measurement and CAD profile design for unique facade, car door, or weather stripping door bottom installations.

- Material Upgrades: For chemical/oil/petroleum/food process application, FDA/NSF/WRAS materials available on request (certification supplied).

- Laboratory Testing: Every lot validated for leakage (@15l/min, 10min), hardness, compression, UV, and salt-fog, per customer country/regulation.

- Packaging and Logistics: Barcoded packaging, batch traceability, flexible shipping terms (Incoterms 2020), suitable for industrial integrators or wholesalers.

Experience & End-User Feedback

- Fleet Maintenance (Germany): “The new auto weather stripping line eliminated wind whistle in 500+ delivery vans — install time per vehicle dropped from 27 to 13 minutes per door.”

- Building Retrofit Contractor (Toronto): “Energy complaints fell by half after application. QC scans using blower-door tests confirmed air leakage dropped by 0.26 ACH.”

- Pipeline O&M (Asia): “After changing to custom rubber profile, annual downtime dropped, with no visible degradation after 5 years in aggressive chemical environment.”

Delivery Lead Time & Warranty

- Standard production: 7–14 days for regular profiles; 25–35 days for new custom die profile after drawing approval

- Quality Assurance: All window weather stripping products covered by 3–5 year warranty (subject to application).

- Support: Live engineer chat, detailed profile matching, sample kits.

- Shipping: Global air/sea or express as per INCOTERMS 2020.

All products comply with ISO 9001:2015 and are tested per ASTM D395, D412, and ISO 9227 standards.

Frequently Asked Questions (FAQ) on Window Weather Stripping & Technical Terms

Q1: What is the optimal durometer for automotive and window weather stripping?

A1: Most high-quality car weather stripping use 60±5 Shore A. This hardness balances flexibility and long-term compression recovery, critical for door/window sealing.

Q2: What does compression set mean, and why is it important?

A2: Compression set refers to a material's ability to return to its original thickness after prolonged compression (e.g., when a car door is closed). A low compression set (≤20–25%) ensures the weather stripping keeps a tight seal over many years.

Q3: What are common industry standards for weather stripping?

A3: Leading standards include ISO 9001, ISO 9227 (salt spray), ASTM D395 (compression set), ASTM D412 (tensile), ANSI Z94.6 (QC). Meeting these ensures product durability, safety, and reliability.

Q4: What’s the best way to install weather stripping door bottom for maximum durability?

A4: Use a degreased, dry surface, apply even pressure for adhesive types, and avoid overstretching. Fastening clips should match the door’s material; professional installation prolongs service life.

Q5: Can window weather stripping be used for industrial sealing (e.g., chemical plants)?

A5: Yes; by specifying EPDM or custom blends (per ASTM D2000), with higher chemical and ozone resistance, window weather stripping can seal hatches, manways, and process windows in harsh environments.

Q6: What is glass run channel in automotive weather stripping?

A6: It’s a U-shaped sealing profile lining the window perimeter, providing a smooth track for sliding glass while blocking water, dust, and noise.

Q7: How is quality assured during production?

A7: Each batch undergoes dimensional, hardness, compression, and water-leakage testing under ISO/ASTM protocols; random samples are aged in UV and salt-fog chambers before approval.

Summary: Why Choose Modern Window Weather Stripping?

- Delivers energy savings, moisture and dust protection, and extended operational life across automotive and building sectors.

- High customization and adaptability for every application, from window weather stripping to complete auto weather stripping overhaul.

- Compliance with global standards and proven performance in the field.

References & Industry Resources

- Allied Market Research: Global Weatherstripping Market Report

- RubberWorld Magazine Technical Archive: What You Need to Know About Weatherstrips

- ASTM Standards for Rubber Sealing: ASTM D2000

- Seattle Retrofit Forum: Window Weatherstripping Retrofit Discussion

- Automotive Sealing Applications – Rubber Europe Journal: Best Practices in Auto Weatherstripping

- QZSeals Official Website: qzseals.com

Compiled and interpreted drawing from global industry data, technical standards, and published case studies, 2024.

Latest news

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025

-

Top Safety Standards for Corner ProtectorsNewsJul.29,2025

-

Step-By-Step Guide to Replacing Garage Door SealsNewsJul.29,2025

-

How to Fix a Loose Under Door Draught StopperNewsJul.29,2025

-

Edge Banding Tape for High-Traffic Commercial SpacesNewsJul.29,2025

-

Best Heat-Resistant Materials for Cooker Door SealsNewsJul.29,2025

-

Weather Stripping Door: Enhance Comfort and EfficiencyNewsJul.23,2025