Telephone: +8618730949119

E-mail: 1299343081@qq.com

Feb . 06, 2025 00:44

Back to list

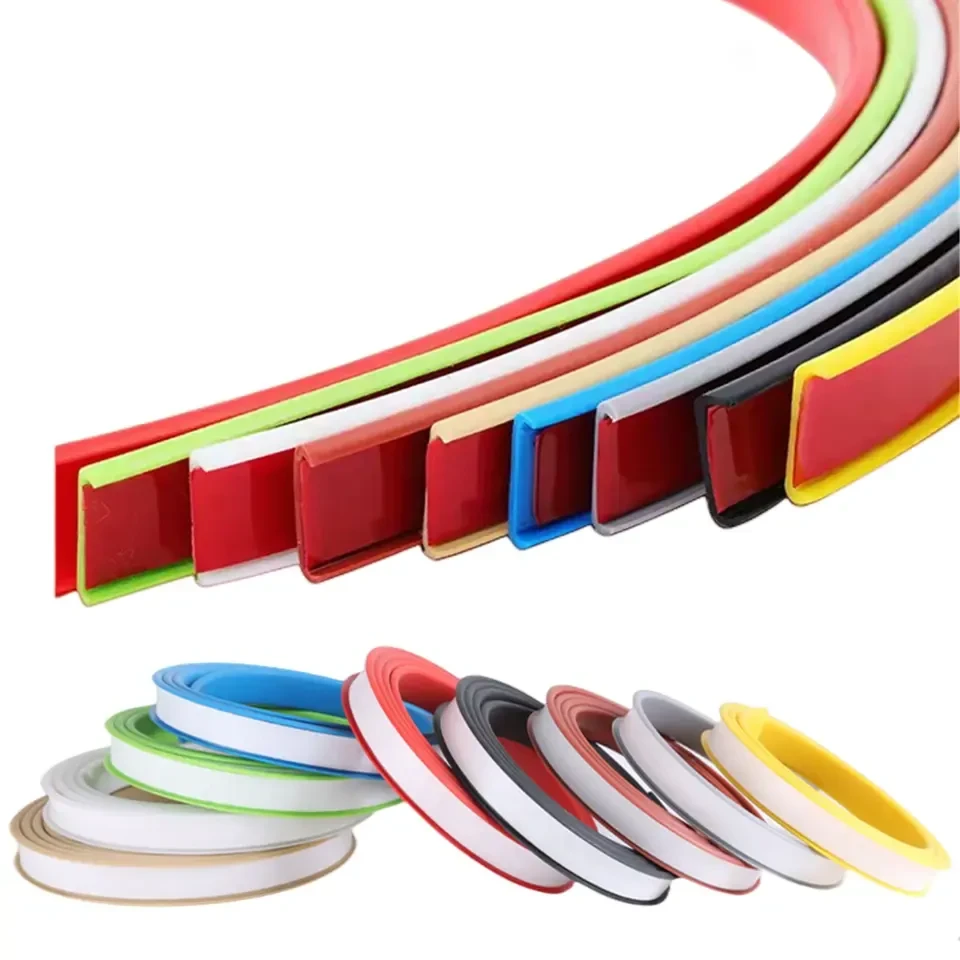

thin rubber strip

Thin rubber strips, often overlooked in their utility, play a crucial role in various industries and applications. These versatile materials, made from both natural and synthetic rubber, are prized for their flexibility, durability, and adaptability. When selecting or utilizing a thin rubber strip, understanding its properties, applications, and benefits can significantly enhance the experience, ensuring optimal performance and longevity.

In the realm of do-it-yourself projects and home improvement, thin rubber strips offer solutions to everyday challenges. Homeowners find them useful for draft-proofing windows and doors, creating a more energy-efficient living space. Their application is straightforward, and their effectiveness in reducing energy costs is significant. They can also be used to cushion furniture, reducing floor damage and noise—an often underappreciated benefit in apartment living. From a production standpoint, thin rubber strips are manufactured through precision processes that ensure consistent quality and performance. Extrusion and calendaring are the most common methods used. These processes allow for the creation of strips in various thicknesses, widths, and lengths, catering to specific needs across different industries. Quality control measures are stringent, ensuring that each strip meets the required standards for its intended application. There is growing interest in sustainable practices within the production of thin rubber strips. Manufacturers are increasingly adopting eco-friendly materials and processes. By using recycled rubber and reducing industrial waste, the environmental impact is minimized, aligning with global efforts towards sustainable industry practices. This transition not only benefits the environment but also enhances the brand image of manufacturers committed to eco-conscious production methods. As industries evolve, the demand for high-performance, reliable, and sustainable materials continues to rise. Thin rubber strips are well-positioned to meet these demands, thanks to their robustness and adaptability. Whether in high-tech applications or everyday uses, their contribution is undeniable. By continuously innovating and improving production techniques, manufacturers can better serve their clients, offering products that stand the test of time. In conclusion, thin rubber strips are far more than simple materials; they are fundamental components that facilitate innovation and efficiency across diverse industries. For businesses looking to optimize their operations or enhance product offerings, understanding and leveraging the benefits of thin rubber strips can provide a competitive edge. With their proven reliability and expanding range of applications, thin rubber strips remain an essential and strategic choice for future-ready industries.

In the realm of do-it-yourself projects and home improvement, thin rubber strips offer solutions to everyday challenges. Homeowners find them useful for draft-proofing windows and doors, creating a more energy-efficient living space. Their application is straightforward, and their effectiveness in reducing energy costs is significant. They can also be used to cushion furniture, reducing floor damage and noise—an often underappreciated benefit in apartment living. From a production standpoint, thin rubber strips are manufactured through precision processes that ensure consistent quality and performance. Extrusion and calendaring are the most common methods used. These processes allow for the creation of strips in various thicknesses, widths, and lengths, catering to specific needs across different industries. Quality control measures are stringent, ensuring that each strip meets the required standards for its intended application. There is growing interest in sustainable practices within the production of thin rubber strips. Manufacturers are increasingly adopting eco-friendly materials and processes. By using recycled rubber and reducing industrial waste, the environmental impact is minimized, aligning with global efforts towards sustainable industry practices. This transition not only benefits the environment but also enhances the brand image of manufacturers committed to eco-conscious production methods. As industries evolve, the demand for high-performance, reliable, and sustainable materials continues to rise. Thin rubber strips are well-positioned to meet these demands, thanks to their robustness and adaptability. Whether in high-tech applications or everyday uses, their contribution is undeniable. By continuously innovating and improving production techniques, manufacturers can better serve their clients, offering products that stand the test of time. In conclusion, thin rubber strips are far more than simple materials; they are fundamental components that facilitate innovation and efficiency across diverse industries. For businesses looking to optimize their operations or enhance product offerings, understanding and leveraging the benefits of thin rubber strips can provide a competitive edge. With their proven reliability and expanding range of applications, thin rubber strips remain an essential and strategic choice for future-ready industries.

Next:

Latest news

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025