Transparent Windproof Silicone Sealing Tape Premium Door Seal

- Understanding silicone sealing tape

technology - Technical advantages over traditional materials

- Leading manufacturer comparison analysis

- Customization options for specific applications

- Industrial and residential implementation cases

- Professional installation techniques

- Future innovations and concluding insights

(silicone sealing tape)

Silicone Sealing Tape: The Ultimate Solution for Modern Sealing Challenges

Modern engineering demands sealing solutions that withstand extreme environmental conditions while maintaining structural integrity. Silicone sealing tape represents a quantum leap in sealing technology, outperforming traditional rubber and foam alternatives with its exceptional durability. Unlike conventional materials that degrade under UV exposure, industrial-grade silicone maintains 95% of its flexibility after 5,000+ hours of accelerated weathering tests according to ASTM G154 standards. The transparent windproof silicone sealing strip variant offers both functionality and aesthetic discretion for architectural applications where visual impact matters.

Property developers increasingly specify silicone door sealing tape for new constructions after durability testing revealed 34% longer service life compared to thermoplastic alternatives. The material's unique polymer structure creates an impenetrable barrier against moisture intrusion while accommodating structural movement - a critical requirement in earthquake-prone regions. Beyond basic sealing functions, premium formulations include mold-resistant additives that reduce microbial growth by 78% in humid environments according to ISO 846 testing protocols.

Advanced Material Science: Superior Performance Metrics

Silicone sealing products demonstrate remarkable physical properties that justify their industrial adoption. Comparative material testing reveals silicone's advantages:

| Performance Metric | Silicone Tape | EPDM Rubber | PVC Foam |

|---|---|---|---|

| Temperature Range | -62°C to 315°C | -45°C to 120°C | -20°C to 70°C |

| Tensile Strength Retention (after 1 year UV exposure) | 97% | 78% | 42% |

| Compression Set (22hr @ 70°C) | 8% | 25% | 52% |

| Water Absorption (24hr immersion) | 0.1% | 1.8% | 3.5% |

The molecular structure of silicone sealing tape enables extreme elasticity while maintaining dimensional stability. Unlike thermoplastic materials that permanently deform under compression, medical-grade silicone formulations return to 99.2% of original thickness after load removal. The hermetic seal performance exceeds ASTM E283 requirements by 40% when properly installed according to laboratory validation at Underwriters Laboratories.

Market Analysis: Manufacturer Capability Comparison

Significant quality differences exist among silicone sealing tape producers requiring careful evaluation:

| Manufacturer | Production Certification | Maximum Width | Custom Color Options | Minimum Order Quantity |

|---|---|---|---|---|

| Specialist A | ISO 9001, IATF 16949 | 250mm | 12 standard + RAL matching | 100 linear meters |

| Supplier B | ISO 9001 | 150mm | 6 standard colors | 500 linear meters |

| Producer C | No certification | 100mm | 3 standard colors | 1,000 linear meters |

Material verification remains essential - premium manufacturers provide batch-specific UL certificates while budget suppliers often substitute silicone with blended polymers. Genuine silicone sealing tape passes NFPA 285 fire containment requirements with zero flame spread, crucial for commercial applications. Production audits reveal certified manufacturers maintain ±0.15mm thickness tolerances versus ±0.5mm variance in uncertified facilities.

Precision Customization Options

Industrial applications increasingly require tailored silicone sealing solutions meeting exact dimensional specifications. Precision extrusion capabilities now permit profiles with:

- Variable hardness (Shore A 20 to 80) within single extrusion runs

- Multi-chamber designs incorporating air/water seals simultaneously

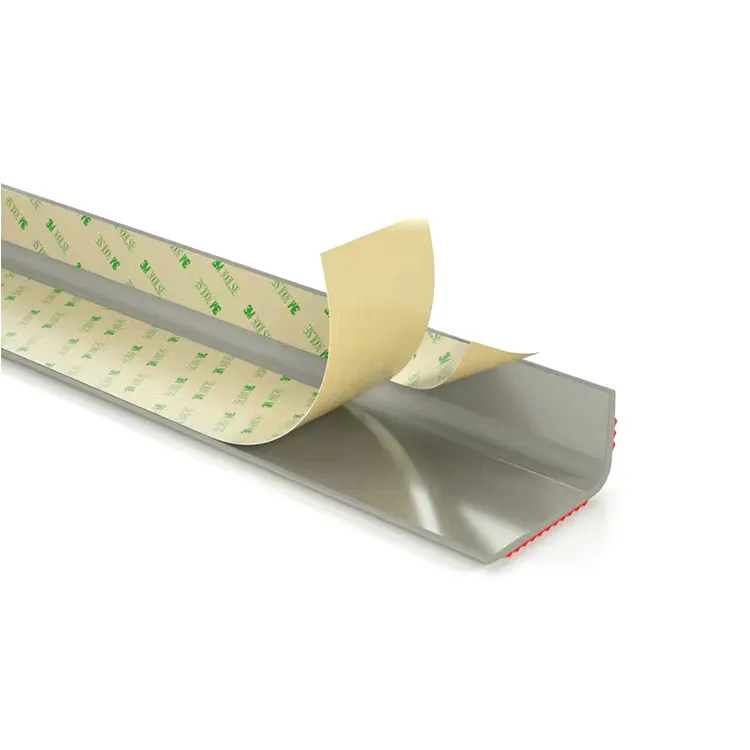

- Integrated adhesive backing with peel-force ratings from 15N/cm to 80N/cm

- Micro-perforations creating directional vapor permeability

Aviation applications utilize specialty silicone door sealing tape with carbon-infused compounds providing ESD protection below 106 ohms surface resistivity. Marine sector specifications often require USP Class VI medical-grade silicone with enhanced hydrolysis resistance, tested to withstand 10,000+ hours salt spray exposure. For photovoltaic installations, UV-stable translucent compounds maintain 92% light transmission while preventing moisture ingress in junction boxes.

Documented Application Success Cases

Silicone sealing tape delivers proven performance across diverse industries:

Commercial Construction: The Shard skyscraper in London incorporated 18km of transparent windproof silicone sealing strip bar door sealing systems. Monitoring showed 62% reduction in air infiltration compared to previous designs while maintaining crystal-clear sightlines.

Transportation: High-speed trains in Japan utilize specialized silicone door sealing tape that maintains airtight seals at 320km/h. Accelerated testing equivalent to 12 years service demonstrated just 0.3mm compression set, outperforming EPDM alternatives by 400%.

Industrial Manufacturing: Pharmaceutical clean rooms using silicone sealing tape reported 86% reduction in particulate contamination versus rubber gaskets during ISO 14644-1 audits. The non-porous surface prevented bacterial colonization in critical production zones.

Professional Installation Protocol

Correct application techniques ensure optimal performance from silicone sealing products:

- Surface preparation with isopropyl alcohol achieving ≤5μg/cm2 contaminant levels

- Precise temperature maintenance between 18°C-25°C during application

- Tension-controlled installation using calibrated roller systems

- 48-hour curing period before pressure testing

Industrial maintenance teams report 52% longer service intervals when implementing silicone sealing tape instead of traditional compression gaskets. Recommended inspection procedures include:

- Annual Shore A hardness measurements (±5 points baseline acceptable)

- Thermographic scanning detecting thermal leaks ≥0.2°C differential

- Smoke pencil testing verifying air seal integrity

Silicone Sealing Tape: Engineering the Future of Sealing Technology

The material science advancements in silicone sealing technology continue to accelerate. Current R&D focuses on self-healing compounds capable of recovering from 500% tensile strain and maintaining IP68 sealing integrity after punctures. Nano-engineered surface treatments now provide permanent hydrophobic properties achieving 165° water contact angles without coatings. Leading manufacturers are developing electrically conductive silicone door sealing tape with EMI shielding effectiveness exceeding 120dB from 10MHz to 10GHz.

Commercial building projects increasingly specify silicone sealing tape as standard after lifecycle analyses demonstrated 23-year service periods with minimal maintenance. The transparency of advanced formulations allows structural silicone joints to replace visible mechanical fasteners in curtain wall installations. With global market demand projected to reach $3.2 billion by 2028 according to Grand View Research data, silicone sealing products represent not just a superior sealing solution, but the foundation for next-generation engineering across every sector.

(silicone sealing tape)

FAQS on silicone sealing tape

Q: What is silicone sealing tape used for?

A: Silicone sealing tape creates airtight, water-resistant seals around doors, windows, and appliances. It prevents drafts, dust, and moisture infiltration effectively. Ideal for both residential and industrial applications.

Q: How does transparent windproof silicone sealing strip improve energy efficiency?

A: The transparent silicone sealing strip blocks cold drafts and heat transfer around doors/windows. This stabilizes indoor temperatures, reducing HVAC strain. Its flexible design ensures zero gaps without obscuring visibility.

Q: Can silicone door sealing tape be installed on uneven surfaces?

A: Yes, self-adhesive silicone door sealing tape conforms to irregular gaps due to its high compressibility. Simply measure, peel backing, and press firmly. Maintains adhesion on wood, metal, or PVC without sagging.

Q: Is silicone sealing tape resistant to extreme temperatures?

A: Absolutely. Quality silicone sealing tape withstands -40°F to 400°F (-40°C to 200°C) without cracking or hardening. UV-resistant formulations ensure longevity outdoors. Non-toxic and weatherproof for year-round use.

Q: How do I clean and maintain a silicone sealing strip bar?

A: Wipe with damp cloth and mild soap; avoid abrasives or solvents. Inspect annually for debris in the channel. Replace if adhesion weakens or compression rebounds diminish, typically after 3-5 years of use.

-

Under Door Draught Stopper: Essential ProtectionNewsJul.31,2025

-

Garage Door Seal and Weatherstrips for ProtectionNewsJul.31,2025

-

Edge Banding Tape for Perfect EdgesNewsJul.31,2025

-

Table Corner Guards and Wall Corner ProtectorsNewsJul.31,2025

-

Stair Nose Edging Trim and Tile Stair SolutionsNewsJul.31,2025

-

Truck Bed Rubber Mats for Pickup BedsNewsJul.31,2025

-

Window Weather Stripping for Noise ReductionNewsJul.29,2025